In the implementation of the project “Research Synergy to address major challenges in the nexus: energy-environment-agricultural production (Food, Water, Materials)” the Institute for Bio-economy and Agri-technology (iBO) has undertaken a series of research activities in the part of the Nexus associated with Nutritional Raw Materials and the assessment of the relevant resources in an environmentally sustainable manner, especially in the stage of the Primary Sector, were the development of intelligent agricultural systems (smart farming) is a decisive stage in the application of low-input circular economy in the agricultural sector. The main goal at that direction is the development and the prototype implementation of an integrated and adaptive farm unit management system that will unify all the existing technologies while using robotic platforms equipped with appropriate sensors and animal and cultivation surveillance systems, fully automating data collection, processing, decision making and intervention.

To design the architecture of the system, its technological requirements were initially defined by determining the technically feasible approaches as well as the equipment and service requirements. Additionally, agronomic and physiology related requirements defined the technical specifications as well as the final model. For the assessment and monitoring of the system appropriate performance indicators (KPIs) covering economic and environmental components have been defined.

A Farm Management Information System (FMIS) has been designed as a central interface for the user and management of the system resources. In order to gain the maximum possible acceptance, existing information systems were initially analyzed and the specifications for the new Farming Management Information System were defined.

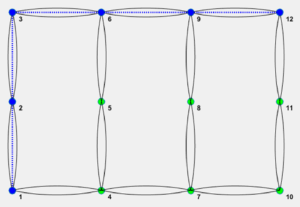

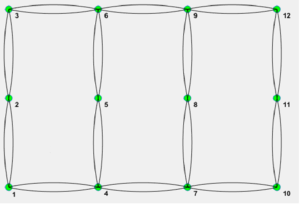

To reassure the successful and effective cooperation of all the subsystems, the merge of the tasks of the proposed systems was designed. Software interconnection plans were carried out, reusable units were identified, all subsystems were interconnected, and their proper and uninterrupted operation was checked.

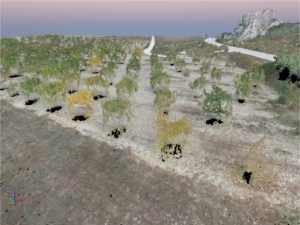

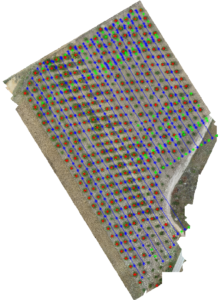

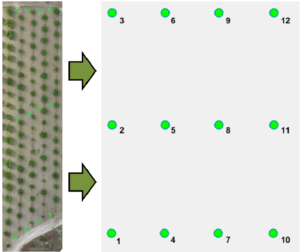

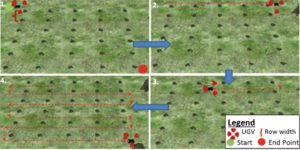

The experimental evaluation of the proposed system is carried out in four (4) indicative and different working environments (orchard, linear cultivation, greenhouse and livestock building) were the real time climatic conditions, air quality and the normal values of cultivations and animals (surface temperature/mobility) are being recorded in the entire field/space that the production system covers. The information is transmitted wirelessly, and the user has access either through a PC or a smart device (smart phone/tablet). The measured data feed appropriate models/algorithms through which the optimal strategies for the management of the production system were proposed (orchard, linear cultivation, greenhouse and livestock building) with the view of producing quality products while reducing input (energy, water, agrochemicals).

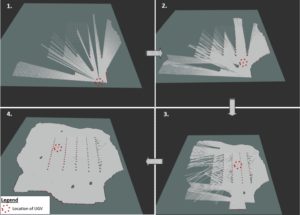

Navigation systems implemented in open and closed spaces were developed. Dynamic routing and surface coverage algorithms developed internally were used. Important element is the synergetic, UGV-UAV, mapping with the use of many autonomous vehicles. Recognition algorithms were developed and used for the detection and the monitoring of moving entities with the basic aim of safety. It was ensured that the robotic vehicles, will be able to perform periodic and automated control procedures with immediate adjustment either in open type production (e.g. linear cultivations) or in closed type production (e.g. livestock buildings), avoiding soil compression or any other damage to the cultivation.

In order to “feed” machine learning algorithms and to extract value-added information, autonomous vehicles carrying sensors, collect data in the field. The analysis of this data and the customization of the system are a part of its functional characteristics.

Emphasis is also given in the environmental sustainability assessment of the proposed techniques and production systems examined in this project, with the use of appropriate environmental impact assessment methodologies. The Life Cycle Assessment (LCA) methodology has been recognized as the most appropriate for that purpose, considering all the stages in the product’s production stage (integrated environmental impact assessment). Thus, it is the most appropriate approach to assess the multidimensional and sometimes contradictory effects of various mitigation of environmental impact techniques on both the system of interest (exploitation) and the overall production chain. In addition to the environmental assessment, indicators of economic viability and social acceptance of the system are also addressed, completing the three main pillars of sustainability.